Cast Heaters

If you’re on the lookout for quality cast heaters, Hedin Heaters is here to help. Over the last 80 years, we’ve been at the forefront of the manufacturing, supply and delivery of all kinds of heater products and parts, including cast heaters.

Cast heaters are excellent at evenly distributing heat, ensuring the longevity of machinery and preventing moisture or contamination. They are essentially a heated part of a tool that can be inserted into all manner of equipment in a variety of industries.

This includes:

- Food machinery

- Extruding

- Packaging machinery

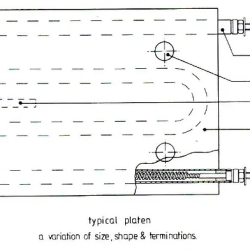

- Hot platens

- Vacuum forming

- Textile equipment

- Heat sealing

- Metal melting

- Compression moulding

- And much more

The basic heat source of our cast in heaters is the tried and tested sheathed heating element. It is flexible in application, robust and utterly reliable. It is rated up to a maximum of 50 watts per square inch, which over the years has proved compatible with long life and reliability.

Delivering cast metal heaters

When you come to Hedin Heaters for electric cast-in heaters, we always take into account your precise specifications. Every customer will require a product of a unique shape and size, as well as with a specific number of holes, slots and thermocouple locations.

Using our advanced technical knowledge, we will tailor the product specifically to suit your heating application.

In addition to our range of cast heaters, we also produce a complete range of ceramic band heaters, as well as ceramic strip heaters and plate heaters, designed to operate up to 750°C.

The ceramic range of heaters are designed to operate at elevated temperatures, where the cast and mica heaters are unsuitable. They are designed and manufactured to suit the customer’s specific application, and offer the same varied range of terminations and control as our cast and mica range of equipment.

To find out more about our cast heaters or any of our other products, contact the Hedin Heaters team today.

When enquiring please specify the following:

- Voltage/wattage

- Length/width/diameter

- Operating temperature

- Location and type of terminals

- Position of holes/slots/temperature probe

- Type of temperature control

- Ideally please provide a sketch